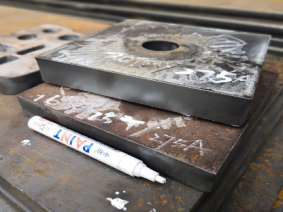

Strict quality control of parts & finished products

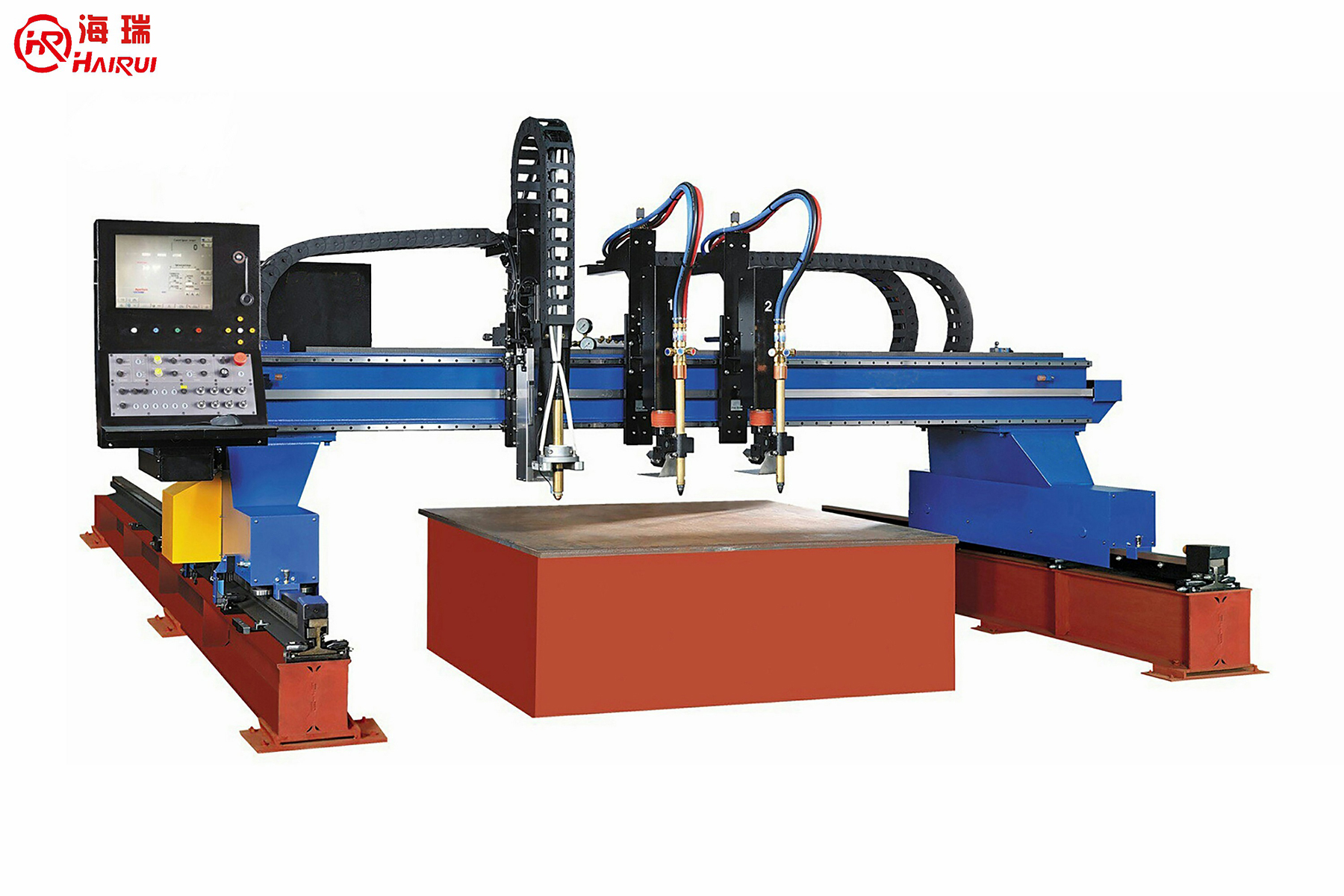

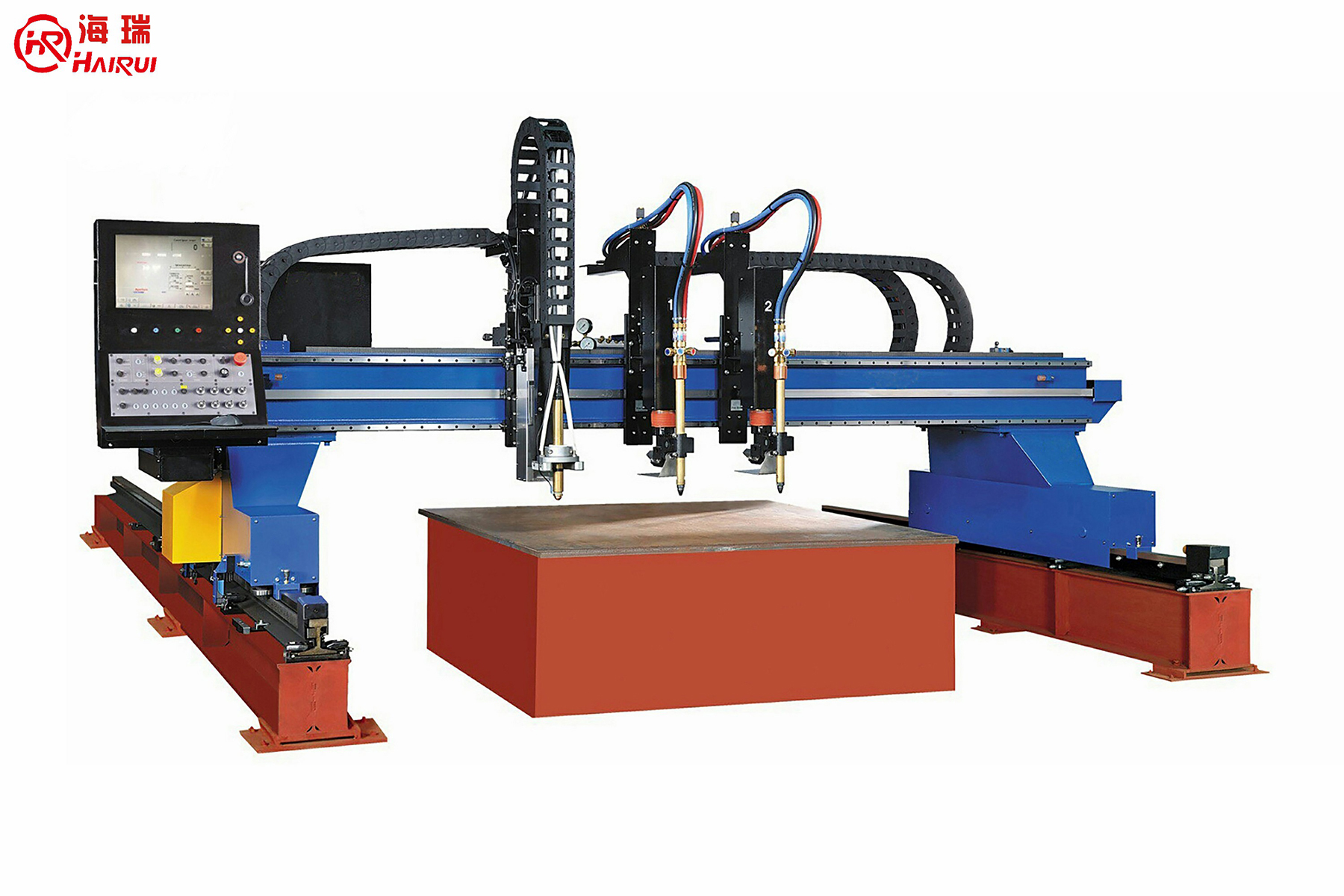

——————————————————————————————————— Hairui gantry CNC flame & plasma cutting machine are known worldwide for their excellent cutting quality.

HRGC-gantry CNC flame & plasma cutting machine is controlled by the CNC system, with the movement of the machine tool, the flame cutting torch & plasma cutting torch installed on the machine tool will cut the plate. Flame cutting and plasma cutting have their own characteristics, flame cutting torch has the ability to cut thick plates, but it can only cut carbon steel, plasma cutting torch can cut all metal materials, but the cutting ability is not as good as flame cutting torch.

The equipment adopts guide rail, machine tool and worktable split structure, when the equipment is installed, the machine tool is directly placed on the guide rail, the standard worktable (made by the customer) is an ordinary worktable, and an optional ventilation system is used to absorb the dust generated by cutting to improve the working environment, it is a high-precision and high-efficiency automatic cutting equipment.

This product can be customized by choosing different guide rail center distance, guide rail length and different number of cutting torches according to actual needs. In addition, straight flame cutting torch, double flame cutting torch, triple flame cutting torch, powder spraying & marking device, automatic height controller, infinite rotary beveling device and drilling device are optional to meet diversified production needs.

According to different configurations, the product can be divided into economical series, standard series, fine small hole series and pipe & plate integrated series. The economical series is driven by stepper motor (optional servo motor), and the other series are driven by servo motor. The standard series can optional equipped with straight flame cutting torch to meet the needs of steel structure manufacturers for cutting strips in batches, the fine small hole series is equipped with fine plasma as standard, and the cutting quality is close to that of laser cutting, without post-processing, the pipe & plate integrated series can choose 2-6 axis customized products according to different pipe cutting needs.

Economical Series

|

Number |

Item |

Detail |

|

01 |

Guide Rail Center Distance |

2000-3000mm |

|

02 |

Effective Cutting Width |

Guide Rail Center Distance-500mm |

|

03 |

Guide Rail Length |

4000-10000mm |

|

04 |

Effective Cutting Length |

Guide Rail Length-1000mm |

|

05 |

Quickly Positioning Speed |

3000mm/min |

|

06 |

CNC Cutting Torch Moving Device |

Max.2 |

|

07 |

Longitudinal Drive Mode |

Stepper (Optional Servo) Bilateral Drive |

|

08 |

IP Grade |

IP54 |

|

09 |

Input Power Supply |

3×380/400/415V, 50/60Hz |

|

10 |

Equipment Main Color |

RAL 5015 Himmelblau or Customized |

Standard Series

|

Number |

Item |

Detail |

|

01 |

Guide Rail Center Distance |

3000-12000mm |

|

02 |

Effective Cutting Width |

Guide Rail Center Distance-800mm |

|

03 |

Guide Rail Length |

Customized |

|

04 |

Effective Cutting Length |

Guide Rail Length-2000mm |

|

05 |

Quickly Positioning Speed |

6000mm/min |

|

06 |

CNC Cutting Torch Moving Device |

Max.12 |

|

07 |

Longitudinal Drive Mode |

Servo Bilateral Drive |

|

08 |

IP Grade |

IP54 |

|

09 |

Input Power Supply |

3×380/400/415V, 50/60Hz |

|

10 |

Equipment Main Color |

RAL 5015 Himmelblau or Customized |

Fine Small Hole Series

|

Number |

Item |

Detail |

|

01 |

Guide Rail Center Distance |

3000-6000mm |

|

02 |

Effective Cutting Width |

Guide Rail Center Distance-800mm |

|

03 |

Guide Rail Length |

Customized |

|

04 |

Effective Cutting Length |

Guide Rail Length-2000mm |

|

05 |

Quickly Positioning Speed |

12000mm/min |

|

06 |

CNC Cutting Torch Moving Device |

Max.4 |

|

07 |

Longitudinal Drive Mode |

Servo Bilateral Drive |

|

08 |

IP Grade |

IP54 |

|

09 |

Input Power Supply |

3×380/400/415V, 50/60Hz |

|

10 |

Equipment Main Color |

RAL 5015 Himmelblau or Customized |

Pipe & Plate Integrated Series

|

Item |

Detail |

|

|

01 |

Guide Rail Center Distance |

4000-6000mm |

|

02 |

Effective Cutting Width |

Guide Rail Center Distance-1800mm |

|

03 |

Guide Rail Length |

Customized |

|

04 |

Effective Cutting Length |

Guide Rail Length-2000mm |

|

05 |

Round Pipe Diameter Range |

50-250/400/500mm |

|

06 |

Tube Ellipticity |

≤1% |

|

07 |

Rotation Axis Effective Distance |

360° Infinite Rotation |

|

08 |

Rotation Axis Quickly Positioning Speed |

8rpm |

|

09 |

Quickly Positioning Speed |

6000mm/min |

|

10 |

CNC Cutting Torch Moving Device |

Max.1 |

|

11 |

Longitudinal Drive Mode |

Servo Bilateral Drive |

|

12 |

Control Axis Quantity |

2 (Standard), 4-6 (Optional) |

|

13 |

IP Grade |

IP54 |

|

14 |

Input Power Supply |

3×380/400/415V, 50/60Hz |

|

15 |

Equipment Main Color |

RAL 5015 Himmelblau or Customized |

|

Pipe Cutting Function Description |

||

|

Two-axis Linkage |

Four-axis Linkage |

Six-axis Linkage |

|

Non-bevel Cutting: Round Pipe |

Bevel Cutting: Round Pipe |

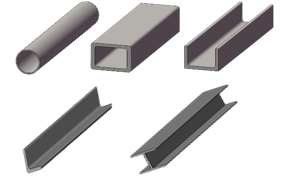

Bevel Cutting: Round Pipe/Square Pipe/Channel Steel/Angle Steel/H-shaped Steel |

|

|

|

|

| Number |

Item |

Configuration |

|

01 |

Oxy-fuel Cutting |

Standard Configuration:

1. Central gas control

2. Oxy-fuel cutting torch

3. Electronic ignition device

4. Automatic height controller

Optional Configuration:

1. Multi-stage fast preheating perforation device

2. Perforation device with fast preheating via proportional valves

3. Digital perforation device with database, perforation thickness up to 150mm, cutting thickness up to 300mm

|

|

02 |

Plasma Cutting |

Optional Configuration:

1. CNC controlled data communication to plasma power source and automatic gas console, so cutting data are sent directly from the CNC controller to the plasma system

2. Plasma height controller with data connection and automatic communication

|

|

03 |

Pipe Cutting |

Optional Configuration:

1. Pneumatic chuck

|

|

04 |

Heavy Duty Cutting |

Optional Configuration:

1. Heavy duty oxy-fuel cutting torch (cutting capacity up to 500mm)

|

|

05 |

Bevel Cutting |

Optional Configuration:

1. Oxy-fuel semi-automatic beveling device

1. Plasma full-automatic beveling device

|

|

06 |

Marking |

Optional Configuration:

1. Plasma marking device

2. Powder marking device

3. Needle marking device

4. Inkjet marking device

|

|

07 |

CNC Drilling |

Optional Configuration:

1. Drilling device (hole diameter up to 32mm, possible max.40mm, thickness less than 80mm)

2. Automatic tool changer for drilling device

|

According to the actual needs of customers, provide corresponding technical guidance and equipment information, answer various questions raised by customers, design plasma processing solutions for customers from technical feasibility, and provide related equipment for customers to visit, sample, test machine.

Sales Service

Investigate the customer’s machine use site, assist the user in planning the layout of the water, electricity, gas and other equipment in the production site according to the actual situation on site, provide the customer with a complete set of equipment operation instructions, and provide training service for the user’s equipment operator. Before delivery, train the user's equipment operators on basic equipment theory, safety protection and equipment maintenance.

After Sales Service

In the user’s factory, the user’s equipment operator is trained in actual processing operations, equipment daily maintenance and safe operation to ensure that the user can familiarize with the equipment operation rules and methods as soon as possible, and can independently use the equipment for production. After the complete set of equipment is installed and debugged at the user’s site, the warranty is free for one year from the date of acceptance by the user. Our company will also arrange technical personnel to conduct technical visits from time to time, communicate with customers on routine maintenance and inspection of equipment, and answer various questions raised by users.

Service Commitment

Service response time within 2 hours, the professional after-sales service team provides 24-hour technical support by email, video, telephone and other communication methods to provide customers with timely, comprehensive, convenient and efficient technical services.