Strict quality control of parts & finished products

——————————————————————————————————— Hairui CNC pipe flame & plasma cutting machine have been developed for efficient pipe processing, which are known worldwide for their excellent cutting quality.

HRPC-CNC pipe flame & plasma cutting machine is controlled by the CNC system, with the movement of the machine tool and workpiece, the flame cutting torch & plasma cutting torch installed on the machine tool will cut the pipe. Different mechanical structures are adopted according to different pipes, the round pipe cutting machine adopts the structure of combining the three-jaw linkage self-centering chuck and auxiliary support devices, the square pipe and special-shaped pipe cutting machine adopts the structure of combining the four-jaw linkage self-centering chuck and the four-jaw unilateral adjustment chuck, it is a high-precision and high-efficiency automatic pipe cutting equipment.

According to the different size and weight of the workpiece, the round pipe cutting machine can be divided into movable lifting bracket, movable roller, rolling bed and other structural forms.

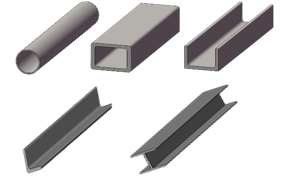

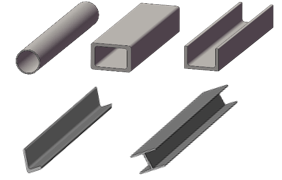

According to the different cutting needs of the pipe, 2-8 axis products can be customized, it can realize the cutting of intersecting line ends and intersecting line holes of round pipes, square pipes and special-shaped pipes, among them, the bevel cutting model is equipped with swing device made of aviation-grade aluminum, which has the advantages of high precision, strong bearing capacity, light weight, small inertia and so on.

8 Axis: main rotation axis, axial moving axis, lifting axis, axial plane swing axis, radial plane swing axis, radial moving axis, vice rotation axis, pipe moving axis.

|

Pipe Cutting Function Description |

||

|

Two-axis Linkage |

Four-axis Linkage |

Six-axis Linkage |

|

Non-bevel Cutting: Round Pipe |

Bevel Cutting: Round Pipe |

Bevel Cutting: Round Pipe/Square Pipe/Channel Steel/Angle Steel/H-shaped Steel |

|

|

|

|

|

Number |

Item |

Detail |

|

01 |

Round Pipe Diameter Range |

60-630/60-800mm 108-1000/219-1210mm 219-1210/325-1620/630-2000mm |

|

02 |

Square Pipe Side Length Range |

80-400/100-500mm |

|

03 |

Pipe Max Length |

6000/9000/12000mm |

|

04 |

Tube Ellipticity |

≤1% |

|

05 |

Rotation Axis Effective Distance |

360° Infinite Rotation |

|

06 |

Rotation Axis Quickly Positioning Speed |

8rpm |

|

07 |

Quickly Positioning Speed |

6000mm/min |

|

08 |

Axial Plane Swing Angle |

±55° |

|

09 |

Radial Plane Swing Angle |

±53° |

|

10 |

Control Axis Quantity |

2-8 |

|

11 |

IP Grade |

IP54 |

|

12 |

Input Power Supply |

3×380/400/415V, 50/60Hz |

|

13 |

Equipment Main Color |

RAL 5015 Himmelblau or Customized |

| Number |

Item |

Configuration |

|

01 |

Oxy-fuel Cutting |

Standard Configuration:

1. Central gas control

2. Oxy-fuel cutting torch

3. Electronic ignition device

4. Automatic height controller

Optional Configuration:

1. Multi-stage fast preheating perforation device

2. Perforation device with fast preheating via proportional valves

|

|

02 |

Plasma Cutting |

Optional Configuration:

1. CNC controlled data communication to plasma power source and automatic gas console, so cutting data are sent directly from the CNC controller to the plasma system

2. Plasma height controller with data connection and automatic communication

|

|

03 |

Pipe Cutting |

Optional Configuration:

1. Pneumatic chuck

|

|

04 |

Pipe Bevel Cutting |

Optional Configuration:

1. Oxy-fuel semi-automatic beveling device

1. Plasma full-automatic beveling device

|

|

05 |

Marking |

Optional Configuration:

1. Plasma marking device

2. Powder marking device

3. Needle marking device

4. Inkjet marking device

|

|

06 |

CNC Drilling |

Optional Configuration:

1. Drilling device (hole diameter up to 32mm, possible max.40mm, thickness less than 80mm)

2. Automatic tool changer for drilling device

|

According to the actual needs of customers, provide corresponding technical guidance and equipment information, answer various questions raised by customers, design plasma processing solutions for customers from technical feasibility, and provide related equipment for customers to visit, sample, test machine.

Sales Service

Investigate the customer’s machine use site, assist the user in planning the layout of the water, electricity, gas and other equipment in the production site according to the actual situation on site, provide the customer with a complete set of equipment operation instructions, and provide training service for the user’s equipment operator. Before delivery, train the user's equipment operators on basic equipment theory, safety protection and equipment maintenance.

After Sales Service

In the user’s factory, the user’s equipment operator is trained in actual processing operations, equipment daily maintenance and safe operation to ensure that the user can familiarize with the equipment operation rules and methods as soon as possible, and can independently use the equipment for production. After the complete set of equipment is installed and debugged at the user’s site, the warranty is free for one year from the date of acceptance by the user. Our company will also arrange technical personnel to conduct technical visits from time to time, communicate with customers on routine maintenance and inspection of equipment, and answer various questions raised by users.

Service Commitment

Service response time within 2 hours, the professional after-sales service team provides 24-hour technical support by email, video, telephone and other communication methods to provide customers with timely, comprehensive, convenient and efficient technical services.