Strict quality control of parts & finished products

——————————————————————————————————— Hairui Intelligent H Beam Assembling Welding Straightening 3 in 1 Machine Production Line are known worldwide for their excellent quality.

Precisely controlled through PLC and HMI, after setting the relevant parameters and welding parameters, one-click start and automatic adjustment for welding.

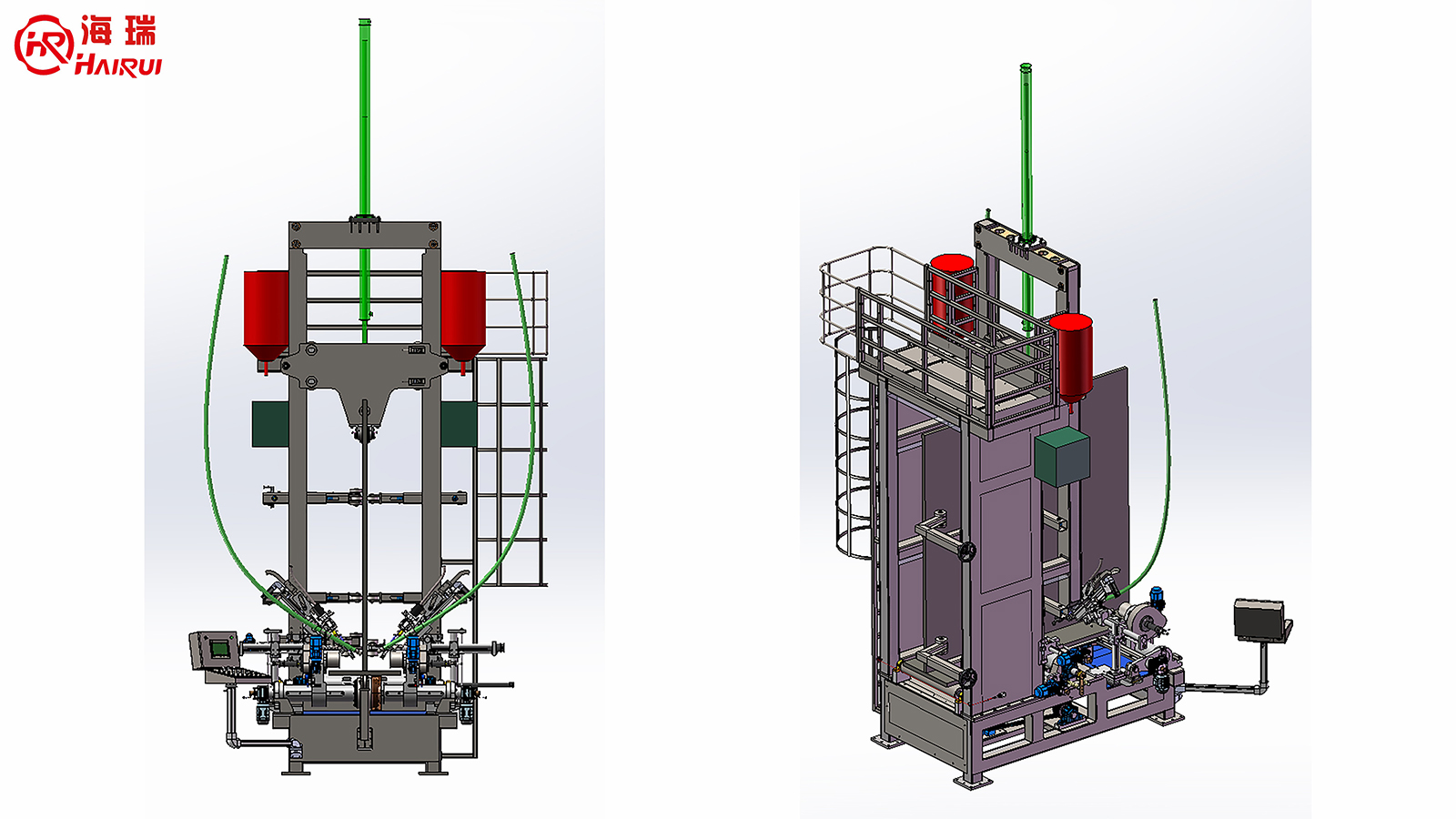

H beam assembling welding straightening 3 in 1 machine is the special equipment for steel structure manufacturers to assembling, welding, straightening H beam, compared with the traditional assembling, welding and straightening split machines, the equipment combines three processes of precise assembling, submerged arc welding and flange straightening after welding deformation in one machine to complete, reduce workpiece circulation to improve production efficiency.

Intelligent H beam assembling welding straightening 3 in 1 machine production line is based on the similar products abroad and our own experience in research and develop H beam welding production line equipment for many years, in response to the market demand, while optimizing and improving the traditional H beam assembling welding straightening 3 in 1 machine to improve its intelligence level, it is equipped with input hydraulic flipping frame, electromagnetic chuck, input web auxiliary positioning bracket, input roller table, input flange & web pre-centering mechanism, input auxiliary bracket & roller table, hydraulic lifting output roller table, output hydraulic flipping frame, chain steel transfer machine and other auxiliary equipment, thus launching a new type of intelligent H beam assembling welding straightening 3 in 1 machine production line equipment.

The intelligent H beam assembling welding straightening 3 in 1 machine production line adopts dual machines and dual stations. The first equipment makes T beam, and the second equipment makes H beam. The two equipment are placed in parallel and staggered. The output roller table of the first equipment and the input roller table of the second equipment are arranged side by side, which is convenient for the T beam made by the first equipment to be moved and flipped to the second equipment for the production of H beam.

The intelligent H beam assembling welding straightening 3 in 1 machine production line adopts double arc double wire submerged arc welding process. Equipped with flux recovery & transportation system, which can automatically recover and transport flux during the welding process, which is convenient and efficient. The speed of welding is stepless adjustable by frequency conversion, the equipment has the advantages of structural compactness, small coverage, fewer operators, stable and reliable operation, high degree of automation, convenient operation and so on, and is intelligent, efficient, ideal equipment to produce H beam.

According to the actual needs of customers, provide corresponding technical guidance and equipment information, answer various questions raised by customers, design laser processing solutions for customers from technical feasibility, and provide related equipment for customers to visit, sample, test machine.

Sales Service

Investigate the customer’s machine use site, assist the user in planning the layout of the water, electricity, gas and other equipment in the production site according to the actual situation on site, provide the customer with a complete set of equipment operation instructions, and provide training service for the user’s equipment operator. Before delivery, train the user's equipment operators on basic equipment theory, safety protection and equipment maintenance.

After Sales Service

In the user’s factory, the user’s equipment operator is trained in actual processing operations, equipment daily maintenance and safe operation to ensure that the user can familiarize with the equipment operation rules and methods as soon as possible, and can independently use the equipment for production. After the complete set of equipment is installed and debugged at the user’s site, the warranty is free for one year from the date of acceptance by the user. Our company will also arrange technical personnel to conduct technical visits from time to time, communicate with customers on routine maintenance and inspection of equipment, and answer various questions raised by users.

Service Commitment

Service response time within 2 hours, the professional after-sales service team provides 24-hour technical support by email, video, telephone and other communication methods to provide customers with timely, comprehensive, convenient and efficient technical services.