Strict quality control of parts & finished products

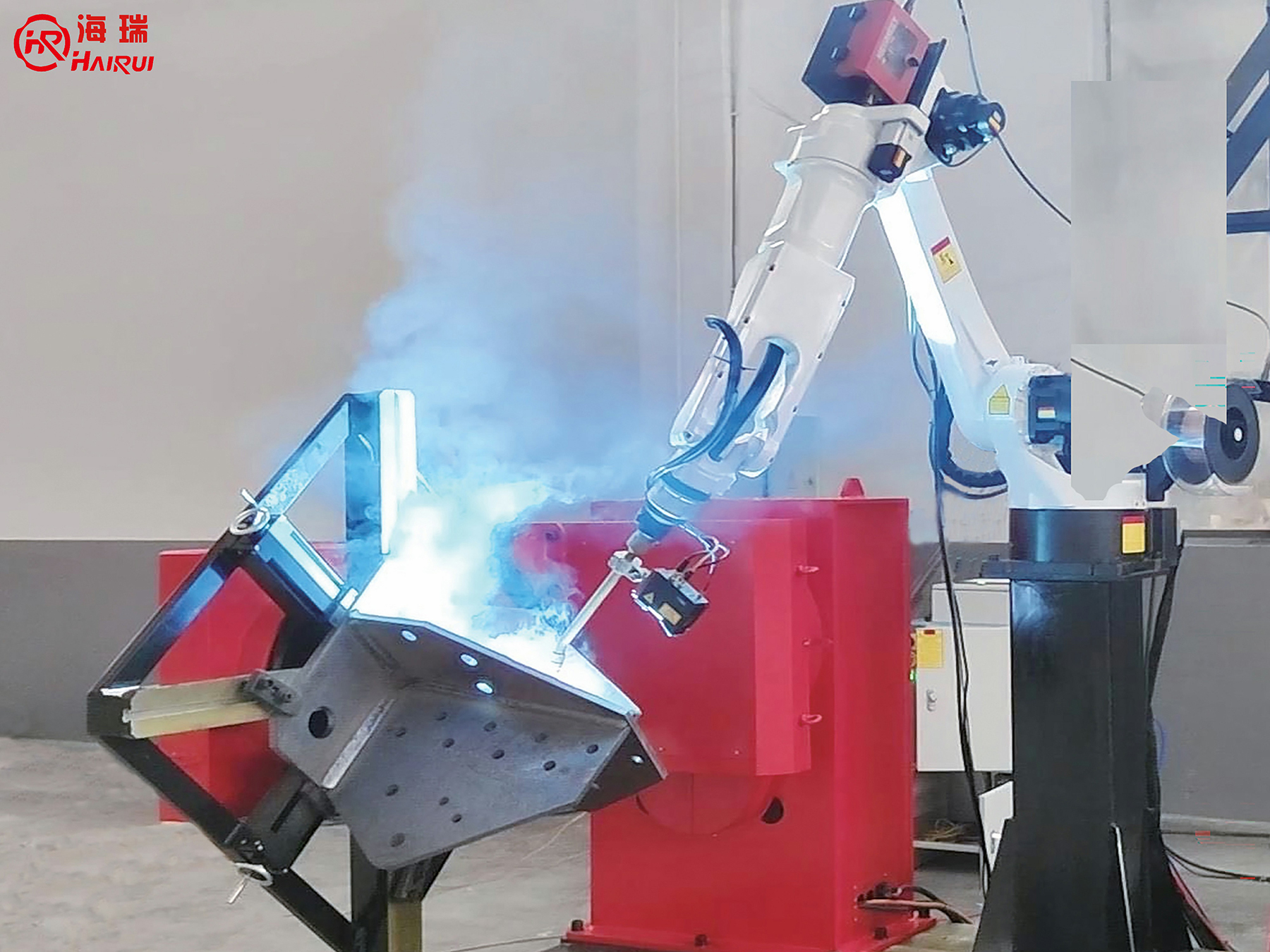

——————————————————————————————————— Hairui intelligent welding robot with positioner are known worldwide for their excellent welding quality.

According to different workpieces and process requirements, different positioner and welding processes can be selected, MIG/MAG welding, TIG welding or laser welding welding process can be selected.

The intelligent welding robot with positioner is mainly used for automatic and efficient welding of complex metal structural parts. It is particularly suitable for large-scale, single-specification metal structural parts.

The intelligent welding robot can adopt fixed type, or various types of structural forms such as ground rail type, cantilever type and gantry type, and be equipped with various types of positioners to perform efficient and intelligent automatic welding. In addition to using teaching programming to generate welding program, it can also be equipped with teaching-free system to automatically generate welding programs by importing three-dimensional model, which can greatly reduce the difficulty of programming. After the welding program is generated, the welding robot automatically performs welding.

The intelligent welding robot with positioner supports multiple welding functions such as path planning, speed planning, swing welding, dynamic modification of welding parameters, wire drawing after welding and so on, and can integrate multiple intelligent sensors such as arc tracking, laser tracking, laser positioning and 3D visual weld recognition.

According to different workpieces and process requirements, different welding processes can be selected, MIG/MAG welding, TIG welding or laser welding welding process can be selected.

According to the actual needs of customers, provide corresponding technical guidance and equipment information, answer various questions raised by customers, design laser processing solutions for customers from technical feasibility, and provide related equipment for customers to visit, sample, test machine.

Sales Service

Investigate the customer’s machine use site, assist the user in planning the layout of the water, electricity, gas and other equipment in the production site according to the actual situation on site, provide the customer with a complete set of equipment operation instructions, and provide training service for the user’s equipment operator. Before delivery, train the user's equipment operators on basic equipment theory, safety protection and equipment maintenance.

After Sales Service

In the user’s factory, the user’s equipment operator is trained in actual processing operations, equipment daily maintenance and safe operation to ensure that the user can familiarize with the equipment operation rules and methods as soon as possible, and can independently use the equipment for production. After the complete set of equipment is installed and debugged at the user’s site, the warranty is free for one year from the date of acceptance by the user. Our company will also arrange technical personnel to conduct technical visits from time to time, communicate with customers on routine maintenance and inspection of equipment, and answer various questions raised by users.

Service Commitment

Service response time within 2 hours, the professional after-sales service team provides 24-hour technical support by email, video, telephone and other communication methods to provide customers with timely, comprehensive, convenient and efficient technical services.